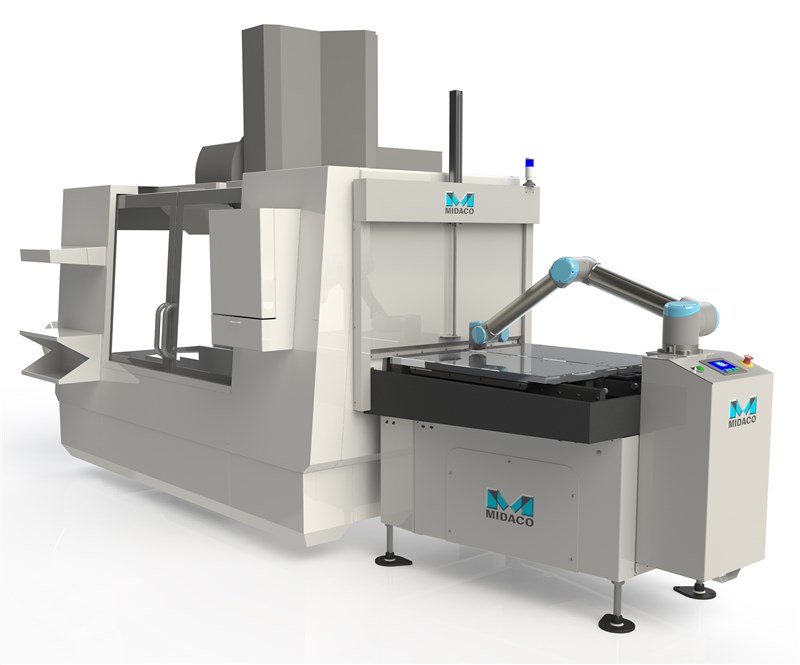

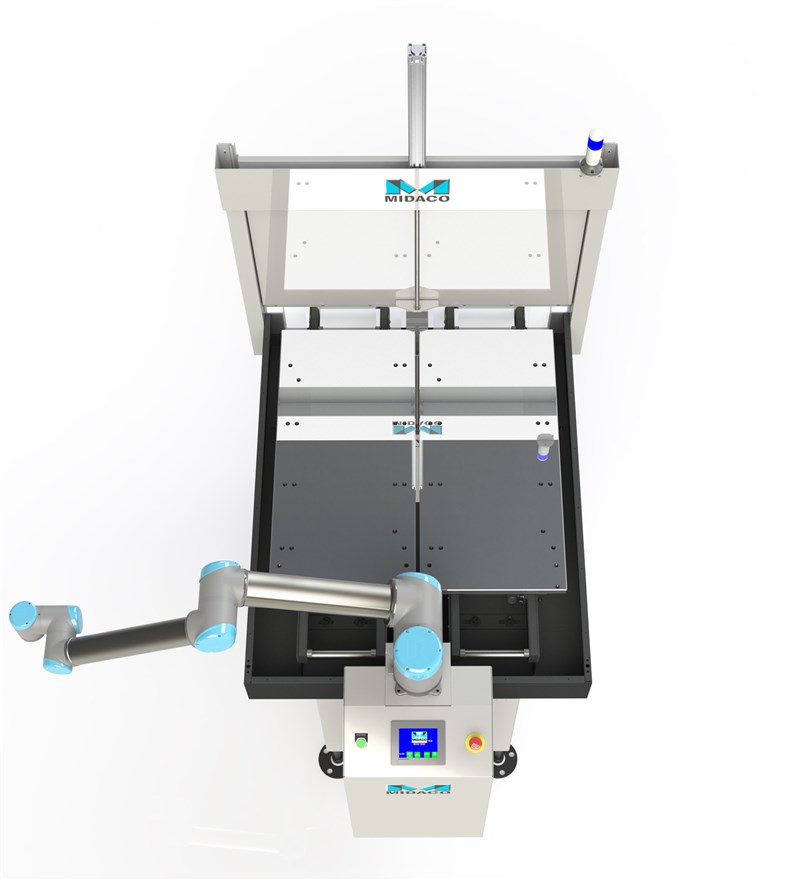

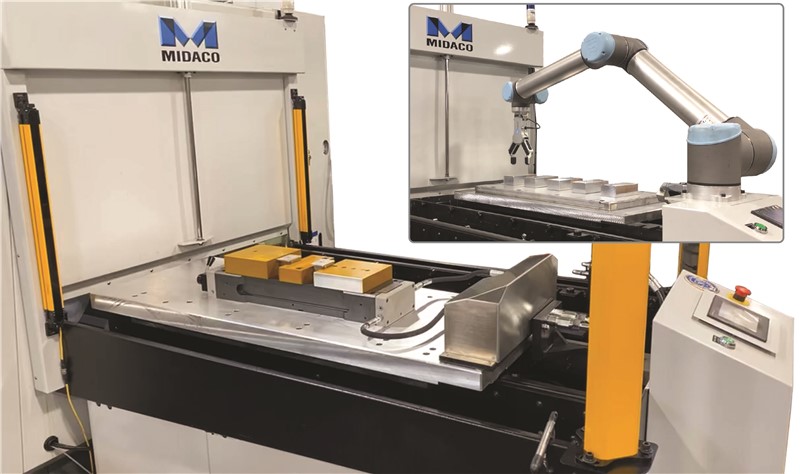

MIDACO Automatic Pallet Changer Mount for Robot/Cobot Arm

MIDACO's A30SD, A40SD and AS50SD series Automatic Pallet Changers can be modified to mount a robot/cobot arm directly on the pallet changer control panel for enhanced collaborative automation. See this new pallet changer modification at SouthTec, October 26-28, 2021 in Greenville SC, MIDACO booth #812.

Step away and let your robot/cobot set-up parts on the pallet changer outside of your VMC while the spindle is cutting.

A robot/cobot mounted directly on the on the shuttle can easily access parts on a table or conveyor set up along-side of the MIDACO Automatic Pallet Changer and do the loading for you with precision and reliability. This modification allows the robot/cobot to set-up parts on the pallet changer outside of your VMC while the spindle is cutting, freeing the operator to perform other tasks.

NOTE: MIDACO requires robot/cobot arm specifications prior to customizing the Automatic Pallet Changer with shuttle mount. Robot/Cobot is to be purchased separately from authorized dealer.

To enhance productivity even further...

The Automatic Pallet Changer can be outfitted with a MIDACO Hydraulic Docking Sytem for automated fixture and vise clamping without the need for hose management. Fixtures stay charged while in the VMC.

The Automatic Pallet Changer can be outfitted with a MIDACO Hydraulic Docking Sytem for automated fixture and vise clamping without the need for hose management. Fixtures stay charged while in the VMC.

For more information:

(847) 593-8420

email: midaco@midaco-corp.com

www.midaco-corp.com