When you are looking to purchase a 3D printer, it can be overwhelming to go through all of the options available on the market. As technology has improved, more and more variations of 3D printers have been developed, so you must find the right one for you.

This ultimate guide will list out the best 3D printers for 2021, as well as their pros and cons according to the top 3D printing service providers!

Choosing the Best 3D Printer

Before we get into specific types of 3D printers, let’s review some important things you should consider before you make your final decision.

Use Case For 3D Printing

For starters, you must ask yourself what you plan to use the 3D printer for. Are you a mechanical engineer that wants to model out some new ideas, or a founder of a hardware product that needs an efficient way to build prototypes?

If so, the best 3D printer for you will be different than someone who is a hobbyist and doesn’t need a commercial machine.

3D Printer Pricing

When you are choosing for the best 3D printer, pricing is another important consideration. The amount you are willing to spend on a 3D printer will also help you narrow down the top choice from this list.

Fused deposition modeling, or FDM printers, will be the most cost-effective. This popular option creates 3D models by heating and extruding plastic.

Stereolithography (SLA) machines utilize ultraviolet light and photosensitive liquid, so these will be slightly more expensive. The most expensive options use selective laser sintering (SLS), which is equipped with lasers that can melt the powder to create the print.

Materials You Will Use With Your 3D Printer

The type of material you plan on printing will also help you determine what the best 3D printer will be for your needs. PLA and ABS are the most common thermoplastics used, and these come in the form of spools of filament that need to be replaced when the printer runs out.

Higher-level models can support materials like wood fill, metal fill, glass fiber infused, and more!

Resolution

Another thing that you need to consider is the level of detail that you need on your print. The smaller the resolution on the printer, the greater level of detail it can create. The micron resolution will vary depending on the model you choose.

THE ULTIMATE 3D PRINTER LIST GUIDE FOR 2021:

Source: FormLabs

Source: FormLabs FormLabs Form 3

Starting off our list of best 3D printers for 2021 is the FormLabs Form 3. This impressive

SLAprinter has a resolution range from 25 to 300 microns and is a relatively small machine considering its high-quality output.

FormLabs Form 3 Pros

This is an ideal choice for superior printing capabilities that support a wide variety of materials. Since it uses a precision laser to create the print, it uses liquid resin instead of solid filament. Although this process will require more time and preparation to complete, the result is worth it!

Simply put, the combination of the technology and breadth of materials available make this perfect for developing prototypes, casting, and production.

FormLabs Form 3 Cons

The main drawback to the FormLabs Form 3 is that the SLA prints require cleaning. Similarly, the cost of this machine is close to $4,000 – so it is not a cheap option.

Source: Ultimaker

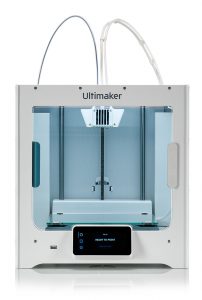

Source: Ultimaker Ultimaker S3

The next 3D printer on our list is the Ultimaker S3. This machine has been a staple in the industry for quite some time, and it comes from of the most reputable manufacturers of 3D printers. The resolution with this machine ranges from 20 to 600 microns, making it ideal for students or others who are creating a wide variety of prints.

Ultimaker S3 Pros

The Ultimaker S3 is known for its quality, speed, and reliability. You can interchange many accessories and materials to fit your unique printing requirements, such as swappable cartridge hotends. Its touchscreen, user interface, and slicer software also lead the market.

This 3D printer is also easy to network, making it extremely usable and business-friendly.

Ultimaker S3 Cons

The only negative thing we can report about the Ultimaker S3 is the cost. This 3D printer starts at around $3,800, so you will need a substantial budget to make this one work!

Source: Monoprice

Source: Monoprice Monoprice Voxel

The Monoprice Voxel is going to be our top choice for the average person. Perhaps you’ve got a tight budget or are just looking to get started with 3D printing without making a substantial investment. If so, this affordable option will be able to meet all of your needs without breaking the bank! The layer resolution goes from 50 to 400 microns, and this model supports a BS, would fill, copper fill, steel fill, and PLA. It has a smaller build volume of 6.9 in, but this lightweight machine is made for smaller projects.

Monoprice Voxel Pros

This 3D model is enclosed, so it is ideal for a small space or even a classroom. It starts at just $400, so it’s an affordable choice that still provides you with impressive speeds and quality. Likewise, the heated print base supports more reliable prints which are perfect for new users!

Monoprice Voxel Cons

When compared to the rest of the printers on this list, the software on the Monoprice Voxel is a bit lackluster. There have also been some Wi-Fi connection issues that users have been frustrated with.

Source: Prusa

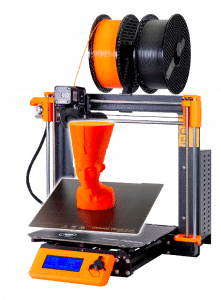

Source: Prusa Prusa i3 MK3S+

The Prusa i3 MK3S+ is also one of our best 3D printers for 2021. This choice provides exceptional print quality due to its advanced calibration techniques imprint monitoring software. The price point is also modest, putting it right in the middle of the price ranges.

Prusa i3 MK3S+ Pros

When it comes to value for your money, the Prusa 3D can’t be beaten. It’s just over $900, but the capability matches those of printers in the $3,000+ range.

The error detection and mitigation systems allow it to be one of the most intelligent 3D printers on the market. this means that you will be creating high-quality prints right out of the box!

There is also a very involved community with excellent support available to help you get this 3D printer up and running.

Prusa i3 MK3S+ Cons

The only drawback to choosing the Prusa 3D model is that the stock configuration struggles to print multiple materials and requires you to change the loaded spool of filament manually. It may not be able to perform as well with hardcore engineering materials either.

Source: Raise3D

Source: Raise3D Raise3D E2

If you need a workhorse 3D printer, then the Raise3D E2 is likely your best option! With this selection, your resolution will range from 20 to 250 microns. Its versatility in design and interface makes it the perfect 3D printer for almost anything!

Raise3D E2 Pros

This printer has a very high resolution, and its touch screen interface is one of the best on the market. It can meet the needs of your business with its impressive integration capabilities and had a straightforward interface.

The Raise3D E2 is extremely reliable and allows you to bring high-end FFF printing right to your home or office!

Raise3D E2 Cons

Besides its steep cost of $3,500, the only real negative to this 3D printer is its large weight and size.

Source: BCN3D

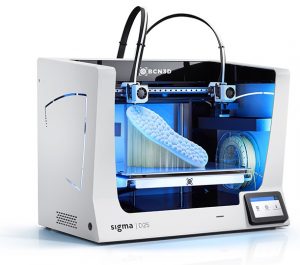

Source: BCN3D BCN3D Sigma D25

When it comes to dual-color printing, the BCN3D Sigma D25 tops the charts. This is a smaller desktop version, but they also have an industrial size made for commercial printing. Another thing that makes this choice unique is that you can use two separate spools of material at one time. As a result, you can either make two copies of something at once or use two distinct material colors to create a multicolor 3D object!

BCN3D Sigma D25 Pros

One of the best things about this 3D printer is that it is fast. It uses automatic calibration tools that are extremely precise and help improve processing times. The wide variety of built-in settings also help!

The BCN3D Sigma D25 is more of an industrial choice, but it maximizes the need for speed and volume. When you combine these capabilities with multiple materials and colors, it’s the perfect edition for your workshop or garage.

BCN3D Sigma D25 Cons

This 3D printer is one of the largest on the list – even the desktop size – coming in at 420mm x 300mm x 200mm. The large build volume requires this much space, so you need to make sure that you have an appropriate place to put it.

Another issue some users have faced with this model is that the setup can be complex, and the English instructions are a bit lacking. Similarly, adding this printer to your workshop will cost you at least $4,000!

Source: Dremel DigiLab

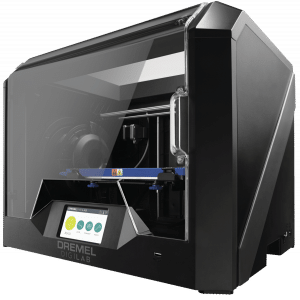

Source: Dremel DigiLab Dremel DigiLab 3D45

The Dremel DigiLab 3D45 is a dependable machine that is relatively affordable, with a price point of $1,700. It can produce a layer thickness ranging from 50 to 300 microns, and the print area covers 10 x 6 x 6.7 inches. Since this 3D printer is easy to use, it is a common choice for classrooms or workshops that conduct training.

Dremel DigiLab 3D45 Pros

When it comes to safety, ease of use, and reliability, the Dremel DigiLab 3D45 is great. The Bosch sensor technology that it has ensures that the machine is safe for any learning environment. Similarly, the carbon filters reduce odors and prevent the release of harmful VOCs. Another benefit of this machine is the excellent print quality, so long as you use the proprietary materials. Setting it up is straightforward too – you can almost use it right out of the box!

Dremel DigiLab 3D45 Cons

Although the closed system is a benefit for safety, it creates a drawback when it comes to creativity. The quality of the prints you produce decreases when you use third-party filaments and the machine has a hard time with materials like nylon. If you want to use tools and materials outside of the Dremel ecosystem, it may not be the right machine for the job.

Source: MakerBot

Source: MakerBot MakerBot Replicator

Next on our list is the MakerBot Replicator. This sturdy 3D printer starts at $1,999, and it can accomplish a lot more than a standard budget printer. It is much faster than older MakerBot models, and much quieter too. The layer resolution reaches up to 100 microns, and the build volume is substantial at 11.6 x 7.6 x 6.5 inches.

MakerBot Replicator Pros

A benefit of the MakerBot Replicator is that it is very quiet. It is much quieter than other models because it uses sound-dampening materials. The software is free and gives you access to many applications and CAD systems. It leads the industry when it comes to downloads, as other printers can use the MakerWare too.

Another benefit of this 3D printer is that it is plug-and-play. All you need to do is take it out of the box, and you are just about ready to get started! The user community also helps, since there are always people willing to share ideas and help you solve any problems that you run into.

MakerBot Replicator Cons

A major disadvantage to choosing this model is that it does not work with ABS filament. The MakerBot Replicator Is ideal for their specialty PLA, but some users have complained that it does not work as well with other materials. An additional drawback to this 3D printer is that it has a weak acrylic build plate. Some have experienced problems where the plate is not flat enough to create certain models, it has even led some to purchase an aftermarket solution.

Source: Creality

Source: Creality Creality Ender 3

If you’re on a tight budget, look no further than the Creality Ender 3. This filament-based option is ideal for the price, considering it starts at only $240. The build area has a volume of 220 x 220 x 250 mm, and it uses a heated build plate to make printing easier. Even though it is affordable, its attributes compete with even the most expensive printers!

Creality Ender 3 Pros

By far the biggest advantage of this model is the price. It has a decent print volume and quality while staying affordable, and the open-source system is helpful. Likewise, it is compatible with flexible filament thanks to the tight filament path it has. The Creality Ender 3 is pretty compact and easy to assemble, so you shouldn’t expect to run into any difficulties there.

Creality Ender 3 Cons

This model isn’t perfect though, and the low price means that the print beds can be a bit flimsy. Other reviews also indicate that the base is known to wobble, so leveling it is difficult. The stepper motors and cooling fans are also very loud, so this is not the best choice for someone looking for a quiet solution. The interface on this 3D printer leaves a lot to be desired. You also have to manually calibrate it, which can be a hassle over time.

Source: Peopoly

Source: Peopoly Peopoly Phenom

The Peopoly Phenom is a big 3D printer, with one of the largest build areas available. It is 10.8 x 6.1 x 15.8 inches – so big is an understatement! This model has a 4K LCD screen with a resolution of up to 72 microns. It retails for just under $2,000, so it falls right in the middle of the price ranges on this list.

Peopoly Phenom Pros

The cost of this machine is a huge pro, considering the print area and the wide variety of materials that it supports. It is more affordable than other leading resin printers, and you can print things almost 16 inches wide!

Peopoly Phenom Cons

The size of this machine can be a drawback, especially if you’re looking to store it in a small area. The Peopoly Phenom also struggles with noise control, so this 3D printer is much louder than some of its competitors. There are many complaints about the confusing interface, and there is no option for it to connect to Wi-Fi.

Source: Artillery

Source: Artillery Artillery Sidewinder X1 V4

The last 3D printer on our list is the Artillery Sidewinder X1 V4. This model only costs about $400 but still provides a broad set of features for beginners and those on a budget. It can handle many types of materials, including ABS, PLA, and TPU. the build volume is also decent, coming in at 11.8 x 11.8 x 15.75 inches.

Artillery Sidewinder X1 V4 Pros

The Artillery Sidewinder X1 V4 is extremely quiet. It is also easy to put together since it almost comes assembled in the box. This 3D printer also heats up very fast, which can cut down on the time it takes to make your models. Overall, it is a very well-designed machine for the price.

Artillery Sidewinder X1 V4 Cons

A weak point on this particular model is the ribbon cables it uses. Even though this makes the printer looks sleek, they are prone to breaking, and the delicate wiring can cause uneven heat dissipation. There are also some known issues with the filament holder.

Which 3D printer Will You Choose?

As you can see, you have quite a few options when it comes to choosing the best 3D printer in 2021. Remember that you should base your choice on how you plan to use it, including which materials you expect to utilize the most.

If you’re new to 3D printing, consider the options with an easy interface and automatic calibration so you can let it do the heavy lifting for you. If you need to use varied materials are multiple colors, then that will determine your selection since not every 3D printer can manage those requirements.

All that’s left to do now is make a decision and enter the exciting world of 3D printing!

If you’d like to discover more about great 3d printers for 2021, you can check out our other lists or media websites like 3dnatives.