We are introducing: our digital detector for easy system integration with variable signal processing and improved electromagnetic compatibility (EMC). Like all detectors from InfraTec, it is based on single-crystal lithium tantalate (LiTaO3) and is used in gas analysis and flame detection . In contrast to other materials, LiTaO3 offers high sensitivity and a good signal-to-noise ratio without additional cooling or temperature stabilisation. For high-precision measurement, especially in gas analysis, synchronisation of the emitter and detector clock is necessary. For the digital pyroelectric detectors, a clock input (pin) is available for this purpose, which is used to specify the system clock or the exact sample time. This allows a time signal with a highly precise sampling rate to be generated. Another special feature compared to analogue technology of our digital detector is the "Fast Recovery after Saturation". This function detects overdriving due to a faulty operating condition – for example, due to extreme temperature fluctuations or mechanical influences – and automatically resets the analogue front-end.

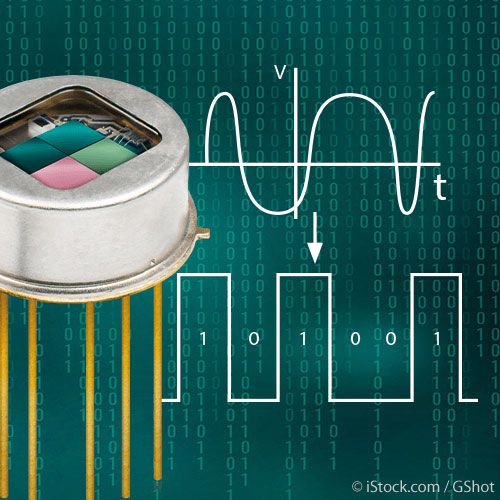

The digital detector converts the analogue signal, which can be filtered and amplified in several stages, directly into a digital signal with a 16-bit resolution. The entire signal processing is carried out by an ASIC (Application-Specific Integrated Circuit), whereby the analogue front-end acts like a classic transimpedance amplifier. Thus, users receive a digital measurement signal that can be read out via an I²C interface and immediately processed.

Digital Pyroelectric Detectors – What are the Advantages?

Simple Integration

The integrated ASIC, which already contains an A/D converter, eliminates complex signal processing steps and the detector can be connected directly to the microcontroller without adjustments. This enables fast and simple system integration. The user is provided with the digital measured values with a sampling rate of up to 1 kHz, which can be read out and directly processed without additional hardware components via the I²C interface.

Improved Electromagnetic Compatibility

The entire signal conversion of the detector is spatially concentrated and shielded, resulting in a higher electromagnetic compatibility (EMC). The detector is more resistant to electromagnetic interference, so that EMC measures can be reduced by the user.

Variable Signal Processing

The most important features for characterising the performance of a pyroelectric detector are the frequency-dependent sensitivity, noise density and detectivity D*. Depending on the measurement system (measurement setup) and principle, there are different requirements for a well-dimensioned signal processing. The digital detector offers full flexibility in the configuration of the detector parameters, during development and also in later use. The sensitivity of the digital detector can be flexibly adjusted depending on the radiated power falling on the detector, in order to optimally utilise the subsequent input voltage range of the A/D converter. Feedback resistor Rf and feedback capacitance Cf can be set individually for each spectral channel of the detector. This allows the user to optimally adapt the performance of sensitivity and stability to the requirements of the application.

Analogue vs. Digital - Which Detector for which Application?

Analogue pyroelectric detectors have proven their worth for decades. Their integration into the device design can be made flexible but requires a high degree of electronic skill. The performance of the detectors can be fully utilised. Considering the effort required for system integration, digital pyroelectric detectors have clear advantages. The functions already integrated into the detector – although limiting the scope for design – significantly reduce the effort required for system integration. We will gladly advise you on the performance parameters of digital and analogue detectors and their suitability for your individual measurement task.