Easily add robotics to your high-mix sanding, grinding, polishing operations and more!

Whether it's labor challenges, reshoring, or market demands, our solutions help you stay prepared for whatever comes your way next.

Get StartedAddress labor shortages and repurpose your team for higher-value and safer tasks.

Every shop is different. Our systems easily adapt and integrate into workflows without costly engineering work.

We use sensors, AI and available CAD data to avoid time-consuming robot programming and upfront setup. Handle high-mix production with ease.

Our robot-as-a-service plan helps you avoid CapEx costs while being able to scale operations as needed.

Get our handy brochure to share with your team. See if the Smart Finishing™ Robotic Workcell is the solution to your production needs.

DownloadFinishing operations are critical to getting product out the door. Repurpose your talented team to higher-value tasks and let our systems handle the Tedious, Dirty, and Dangerous.

Our Smart Finishing™ Robotic Workcell integrates advanced sensors and cameras with popular industrial and collaborative robot arm OEMs to deliver a turnkey, pre-engineered surface finishing solution in high-mix operations.

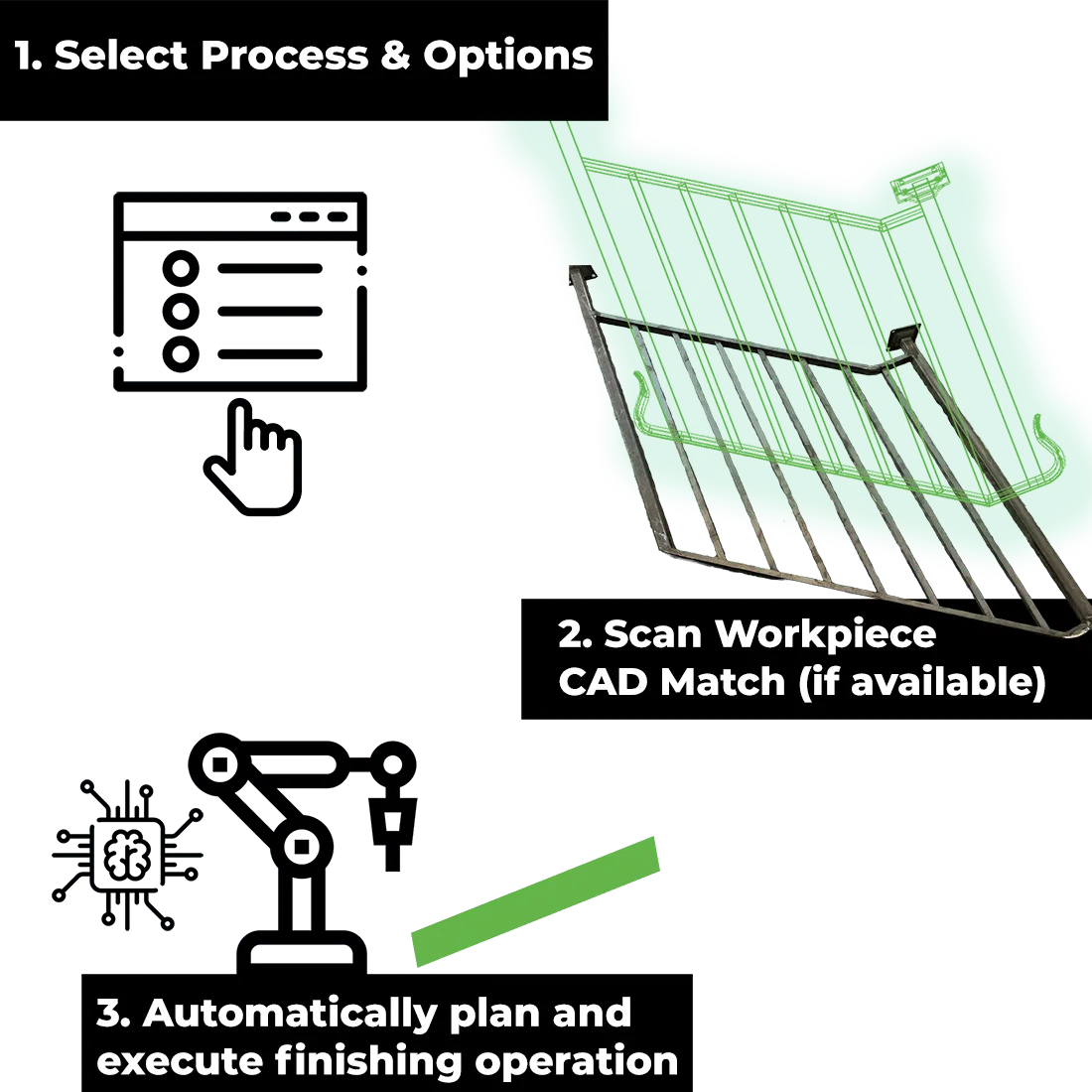

Select desired finishing process and details. For example, specify a Stainless Steel No. 4 polish finish.

Our system uses integrated cameras and other sensors to scan the workpiece. We'll use available CAD models for additional matching.

Using the sensor data and model, the robot automatically plans a robot motion and finishing process path. No programming required!

Robot executes the finishing process and uses sensors to monitor progress. No babysitting, freeing up operators for other tasks.

Finishing processes can be found in nearly every industry, each with their own requirements and operational details. Easily integrate our systems or contact us to discuss customization options.

Our technology eliminates the need for costly and time-consuming robot programming to support low-volume production. Small business without an in-house automation team? We've got you.

Take the first step to supercharge your high-mix operations. Typical system payback is as little as 6 months. We'll provide a customized, free analysis for your operations.