Truly Accurate Job Costing

Get the full story on job costing when you automatically gather and combine machine cycle time with operator labor records.

Automate Manual Steps

Automate non-productive tasks and manual steps like labor tracking, program loading, work instructions, check sheets, and support requests.

Prevent Scrap & Mistakes

Our RFID technology always matches the correct job to the right CNC program, offsets, and work instructions, eliminating human error at the CNC.

Next Gen Shop Communications

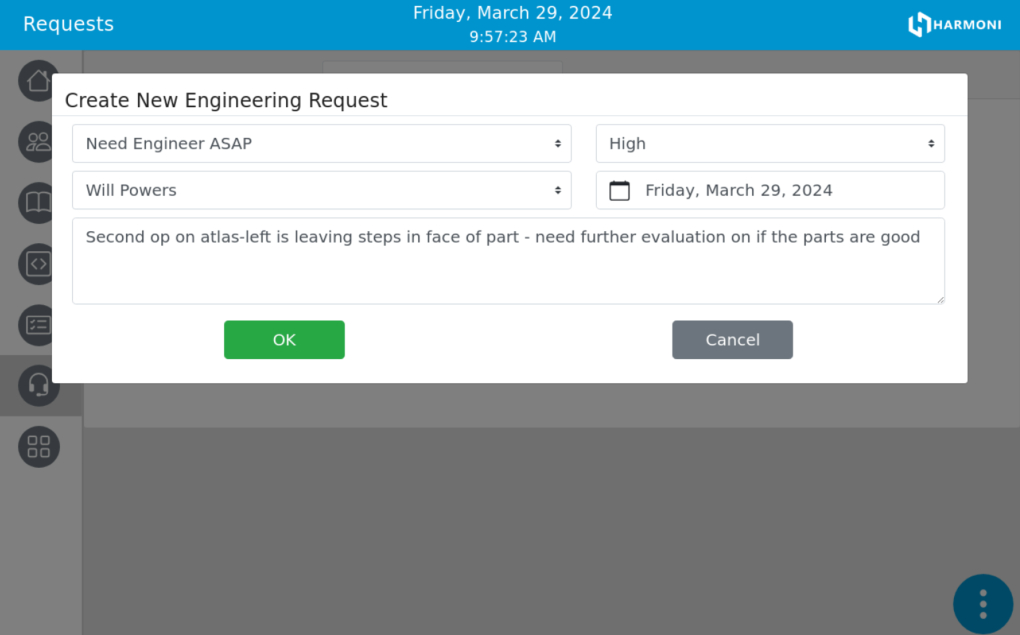

Eliminate wasted time and increase efficiencies by allowing operators, support, and management to communicate directly from desktop to CNC machines.

Real-Time Information

Harmoni brings together data from operators, CNC machines, and your shop floor software, all in real-time, to help managers make decisions and spot trends quickly.

Increase Production & Efficiency

Harmoni keeps CNC machines and operators working, at peak levels, eliminating wasted time, reducing manual steps, eliminating scrap, and making communications a breeze.

Shop Floor Dashboards

Harmoni goes way beyond machine monitoring. Truly understand if your operators and CNC machines are operating at acceptable levels, in real-time, right from your desk.

All Your Data Working Together

Harmoni brings CNC machines, operators, shop floor software, and quality systems together – imagine everything working in Harmoni!

What is Harmoni?

Real-time CNC Machine Monitoring, OEE, and Data Collection

Harmoni (patent pending) is the #1 solution for real-time CNC machine data collection — everything from a CNC machine monitoring platform, real-time OEE, & labor & job data collection — all accomplished via long-range RFID.

By connecting to your CNC machines, operators, and shop floor systems, Harmoni acts as a powerful machine monitoring system that truly connects your entire machine shop and manufacturing processes together. By automatically detecting nearby employees, machine tools, and jobs, Harmoni automates unproductive data collection and production tasks, all while eliminating potential mistakes and human error.

We simplify the entry of time records into ERP systems, collect machine data, help eliminate machine downtime, load the correct programs for the detected part revisions, and combine machine data with transactional real-time data to provide a holistic view of shop capacity and performance.

What is Harmoni?

Real-time CNC Machine Monitoring, OEE, and Data Collection

Harmoni (patent pending) is the #1 solution for real-time CNC machine data collection — everything from a CNC machine monitoring platform, real-time OEE, & labor & job data collection — all accomplished via long-range RFID.

By connecting to your CNC machines, operators, and shop floor systems, Harmoni acts as a powerful machine monitoring system that truly connects your entire machine shop and manufacturing processes together. By automatically detecting nearby employees, machine tools, and jobs, Harmoni automates unproductive data collection and production tasks, all while eliminating potential mistakes and human error.

We simplify the entry of time records into ERP systems, collect machine data, help eliminate machine downtime, load the correct programs for the detected part revisions, and combine machine data with transactional real-time data to provide a holistic view of shop capacity and performance.

As Featured In…

Features

Real-Time CNC Machine Monitoring

Accurately monitor your CNC machines and equipment in real-time from anywhere.

Work Instructions

Automatically pull up the correct work instructions, drawings, and setup sheets associated to job RFID tags.

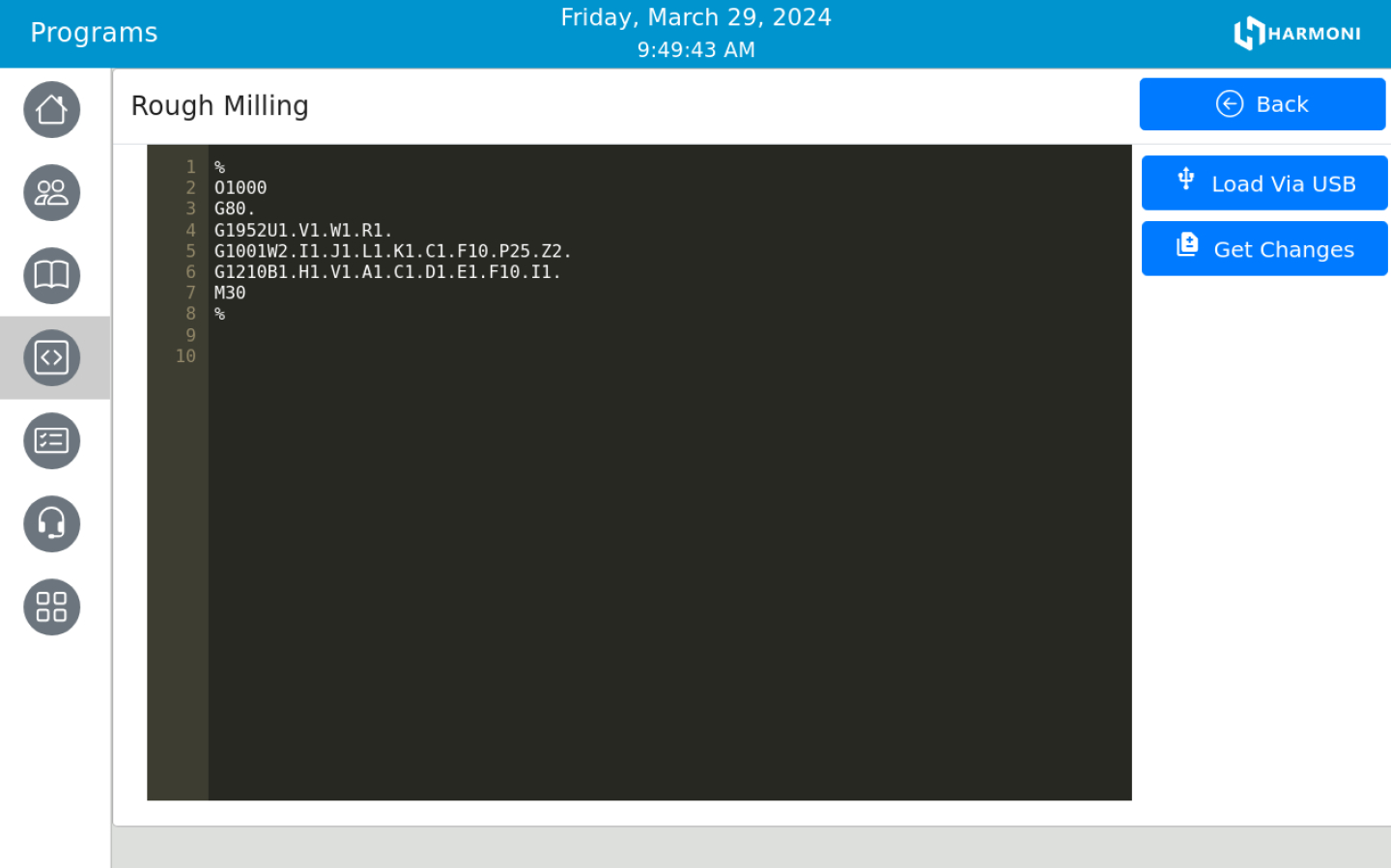

Automated Program Loading

Improve setup times and eliminate costly mistakes by loading programs, settings, and offsets by RFID.

Digital Checksheets

Allow operators to track feature measurements digitally and observe trends in order to monitor quality trends in real-time.

Next Generation Shop Communications

Initiate calls to/from devices to provide engineering and maintenance support without ever leaving the work center.

Your CNC Knows Who You Are & What You’re Working On

Using RFID technology, your employees can walk up to their machine and it will know who they are, what they are working on, load their program, track their time, and show them work instructions.

Easily Track Your Employee & Machine Time in Your ERP

As your employees use Harmoni throughout the day, it automatically tracks both employee labor and machine production time. All of that time data can be pushed into your ERP or shop software system, to better understand job costing and profitability.

Always Load the Right CNC Program For Your Part & Machine

Harmoni knows which program needs to be loaded for a particular machine and the part revision associated with the current job. Utilizing the correct CNC program ensures accuracy and helps to eliminate scrap and waste. No more time wasted trying to figure out which program to run.

Display the Current Work Instructions For Each Job & Machine

Harmoni allows your machinists to access the most up-to-date work instructions for the job or machine that they are working on. This helps to ensure ISO compliance and keep your quality procedure accessible.

Your CNC Knows Who You Are & What You’re Working On

Using RFID technology, your employees can walk up to their machine and it will know who they are, what they are working on, load their program, track their time, and show them work instructions.

Easily Track Your Employee & Machine Time in Your ERP

As your employees use Harmoni throughout the day, it automatically tracks both employee labor and machine production time. All of that time data can be pushed into your ERP or shop software system, to better understand job costing and profitability.

Always Load the Right CNC Program For Your Part & Machine

Harmoni knows which program needs to be loaded for a particular machine and the part revision associated with the current job. Utilizing the correct CNC program ensures accuracy and helps to eliminate scrap and waste. No more time wasted trying to figure out which program to run.

Display the Current Work Instructions For Each Job & Machine

Harmoni allows your machinists to access the most up-to-date work instructions for the job or machine that they are working on. This helps to ensure ISO compliance and keep your quality procedure accessible.