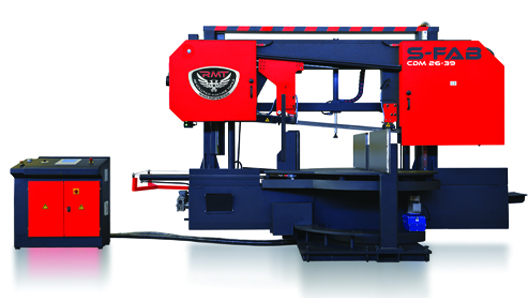

The Revolution Machine Tools™ S-FAB™ CDM 26-39 Semi-Automatic Column Type Double Miter Bandsaw has a cutting capacity of +60/-45 straight and angled cuts designed to perform fast and cutting at desired angles. The cutting capacity of this machine is 26” x 39” in 90° flat cuttings and Ø26” in round material. The precision of this machine allows it to cut percentage angles. The touch panel has made the machine easy to use. Fault finding, cutting follow-up and option selection are simplified with our control panel menus. The rollers on the table are designed for easy movement of the material on the machine. It has minimized the errors that may occur in cutting with its automatic strip tensioning feature. The lane condition is hydraulically controlled. The S-FAB CDM 26-39™ has made a rapid descent until it sees the material to be cut, thus shortening the time of cuts made in varying sizes. Thanks to the rotating hub, the angle of the head is changed, not the angle of the material, thus saving a considerable amount of space. Upper body and arm movements are made with precision linear slide bearings.

The S-FAB™ CDM 26-39 Bandsaw comes standard equipped with a control panel, motorized blade brush, hydraulic vise, security switch, Siti heavy duty gearbox, infinite variable speed inverter, sensitive pressure control, hydromechanical blade tension, optical saw height adjustment, linear guide rails, turn table, turn table brake, proximity switch for sensing blade slippage, chip conveyor, coolant pump, digital readout, and 230V or 440V 3 phase power.

Buyers have the option to add any of these additional features to their S-FAB™ CDM 26-39 Bandsaw as well: Hydraulic blade tension, hydraulic top clamping, DropsA air/oil clean lubrication system, micromist cooling, 10ft roller table with the option to make the table motorized, laser line, and NC control system.

S-FAB CDM 26-39 SPECIFICATION

|

Metric |

US |

| Round - Capacity at 0° |

650 mm |

25.6" in |

| Flat (H x W) Capacity at 0° |

600 x 1000 mm |

23.6" x 39.8" in |

| Square - Capacity at 0° |

600 mm |

23.6" in |

|

|

|

| Round - Capacity at 30° |

650 mm |

25.6" in |

| Flat (H x W) Capacity at 30° |

600 x 840 mm |

23.6" x 33" in |

| Square - Capacity at 30° |

600 mm |

23.6" in |

|

|

|

| Round - Capacity at 45° |

650 mm |

25.6" in |

| Flat (H x W) Capacity at 45° |

600 x 660 mm |

23.6" x 26" in |

| Square - Capacity at 45° |

600 mm |

23.6" in |

|

|

|

| Round - Capacity at 60° |

440 mm |

17.3" in |

| Flat (H x W) Capacity at 60° |

600 x 440 mm |

23.6" x 17.3" in |

| Square - Capacity at 60° |

440 mm |

17.3" in |

|

|

|

| Round - Capacity at -30° |

650 mm |

25.6" in |

| Flat (H x W) Capacity at -30° |

600 x 840 mm |

23.6" x 33" in |

| Square - Capacity at -30° |

600 mm |

23.6" in |

|

|

|

| Round - Capacity at -45° |

650 mm |

25.6" in |

| Flat (H x W) Capacity at -45° |

600 x 840 mm |

23.6" x 33" in |

| Square - Capacity at -45° |

600 mm |

23.6" in |

|

|

|

| Cutting Speeds |

20-100 m/min |

65-328 ft/min |

| Band Dimension |

8400 x 54 mm |

330.7" x 2" in |

| Main Motor |

7.5 kW |

10 HP |

| Hydraulic Motor |

5.5 kW |

7.5 HP |

| Weight |

6250 kg |

13,779 lbs |

| Machine Length |

4750 mm |

788" in |

| Machine Width |

2270 mm |

90" in |

| Machine Height |

2630 mm |

104" in |

LEARN MORE HERE

BANDSAW CATALOG

BANDSAW VIDEOS